Idaho Falls, ID-based Resin Architecture (Resin), led by founding principles Graham Whipple, Jonathan Gallup and Greg Croft has been working with Archicad in a way that supports the case for an integrated building team.

The firm’s roots with Archicad run deep – from the experience of its principals. Sown with a desire to push boundaries and enriched by the goal to establish a strong foundation as a non-traditional, cutting-edge firm, Resin has for the past several years worked with a local structural and mechanical engineer to use the same software.

The integrated team’s experience was something I knew was possible with Archicad

Graham Whipple, Principle, Resin Architecture

The desire for an integrated team

“The integrated team’s experience was something I knew was possible with Archicad,” explained Whipple. “I pushed my structural engineer to use Archicad because I wanted them in my model. For a solid three years now, since Jonathan and Greg came together with me to officially form Resin Architecture our practice has innovated our workflows and looked at ways we could streamline integration with our engineers.”

Whipple admits that it took time to develop traction with his structural engineer. It involved what he considers important in-person training that supplemented screen sharing and virtual training sessions which had been occurring prior to Resin’s founding. By the time Resin converted fully to Archicad by mid-2018, he says the investment had paid off.

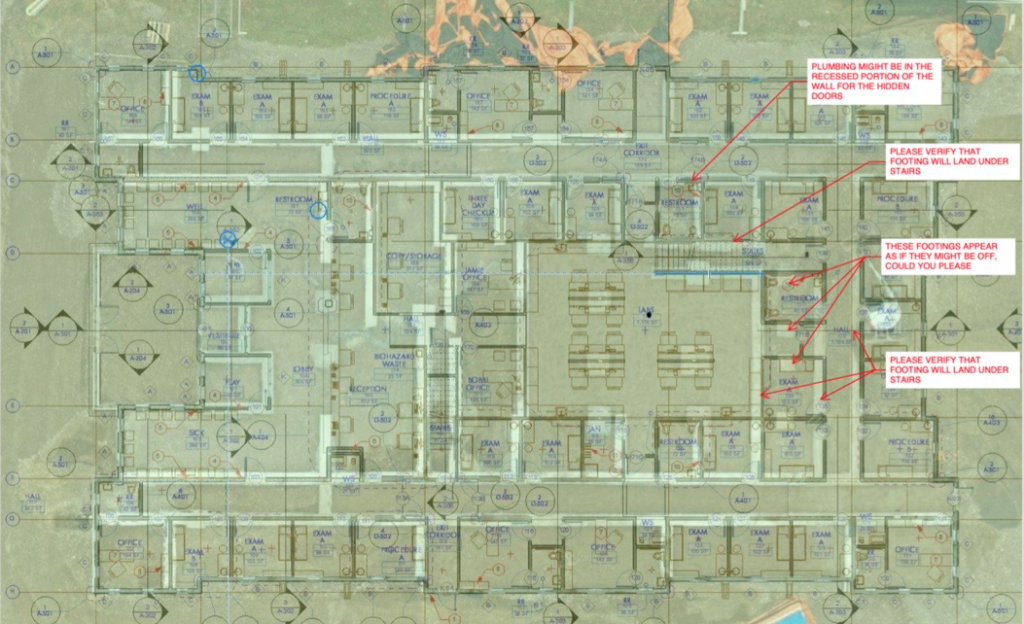

“At that point we’d won a significant project for our region – Idaho Falls Pediatrics. Two of our users jumped in to work on it completely cold in terms of knowing Archicad, and over the months that followed, they executed beautifully,” according to Whipple. Croft clarified, “we had been in the software completely for about four months as users new to the software. I attribute much of our success there to our having our structural engineer, Frost Structural Engineering, already in this model.”

“Our entire firm took advantage of the specialized training that BIM6x organized,” said Gallup. “It opened our eyes to the future of our office, the future of Archicad. A main takeaway was the ability to push boundaries – learning how to do laser scans with Matterport cameras, how to integrate point clouds into modeling, and to do photogrammetry through drone captures. That’s what has supported us in continued pushing to coordinate and collaborate with our mechanical engineers. We know the software supports it.”

These Archicad users do not pull punches when they say it takes work to set it up. Yet they all adamantly attest the work pays off in a myriad of ways.

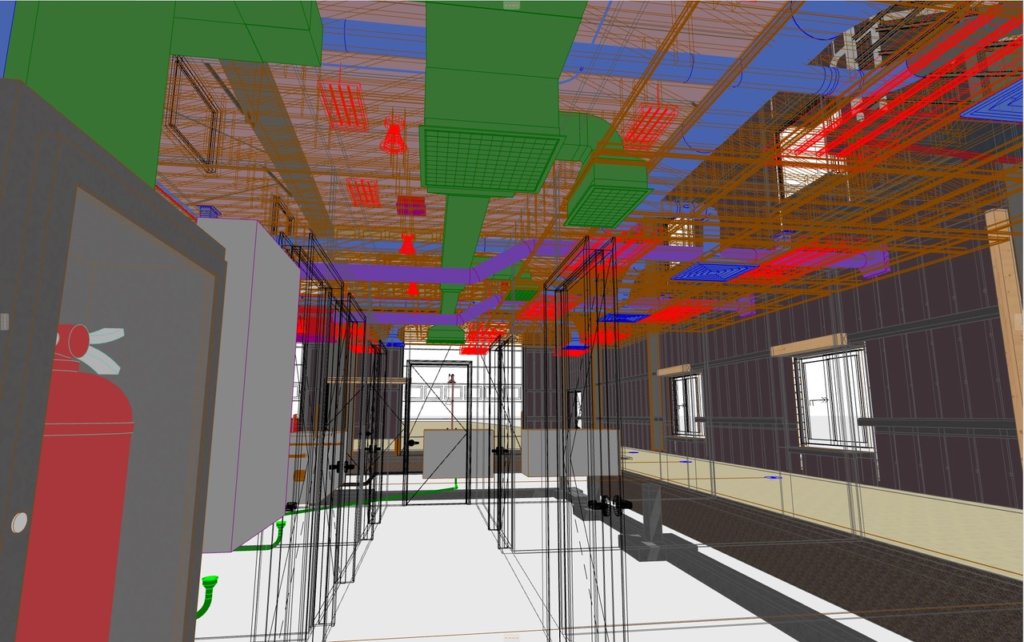

“When we first came together in 2017, we were modeling in all the duct work and coordinating it for our own coordination purposes. But that was not good enough,” explains Gallup. “We kept asking, ‘Why should we be doing that modeling when we have the mechanical engineer engineering it all?’ so we kept pushing and working with our local engineers, going back and forth a few times on a few test projects, where they would export and their Z coordinates would be way off, and the duct work would be way off, and our modeling. We trained, and trained, and trained, but, boy, now that we have our structural engineer on our same model as us and our mechanical engineer is huge. Archicad contributes phenomenal coordination and power to the success of the project.”

Archicad contributes phenomenal coordination and power to the success of the project.

Johnathan Gallup

Enhancing communication with BIMx

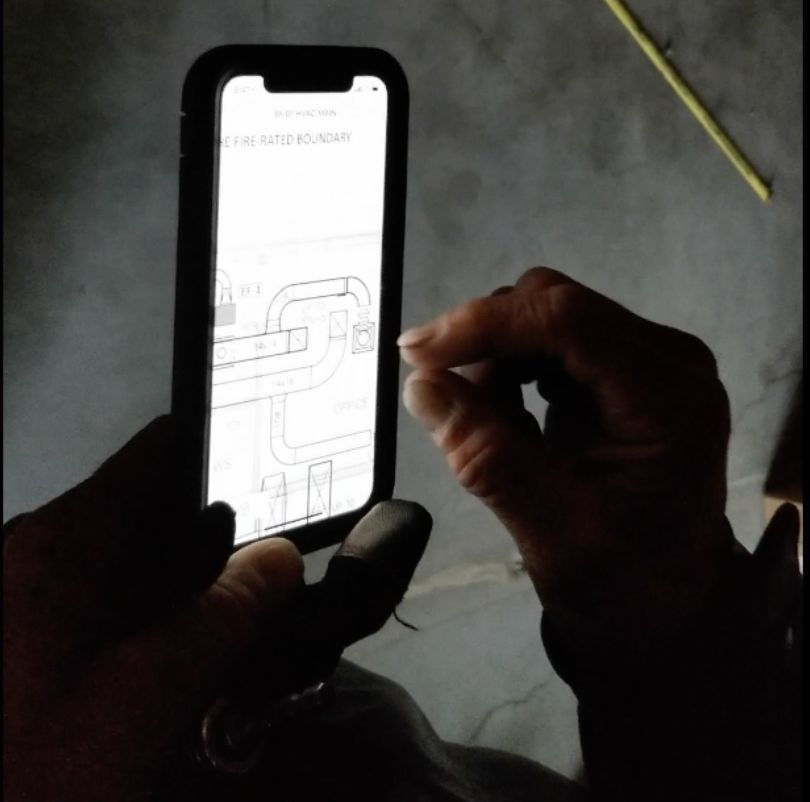

Graphisoft’s award-winning presentation app, BIMx, had a role to play as well on the Idaho Falls Pediatrics project, adds Whipple. He shared one anecdote involving an HVAC contractor who relied on the BIMx model loaded to a smart phone to discuss ductwork routing from the site.

“That was incredibly powerful. While many may assume the ultimate goal of BIMx is getting it into our clients’ hands – getting it into the hands of the subcontractor is a game-changer. For us it was an eye-opener as well to further improve how we were making sure our HVAC, plumbing lines, significant building systems, electric were accurately modeled.”

That “ah-ha” moment led Resin to seek tight integration with their local mechanical engineers in addition to structural. The task for the team was to convey benefits, so they really examined how many times they needed to re-engineer a certain transition, or a fitting, or reroute ducting because of a conflict with the beam, or a column, or it doesn’t match with the intent of the architectural design for a framed ceiling soffit or a transition in the ceilings, et cetera. Enter Elemental MEP with a willingness to learn and stretch their capabilities into a new software.

“We had willing partners. For that we are grateful. We have now been working with Elemental on quite a few projects where we’re integrating. It takes continuous checking in at the outset. Paying attention to getting the model to display the way they need it to is a small price to pay for not having to resort to any external software for the modeling, it is one model,” says Whipple.

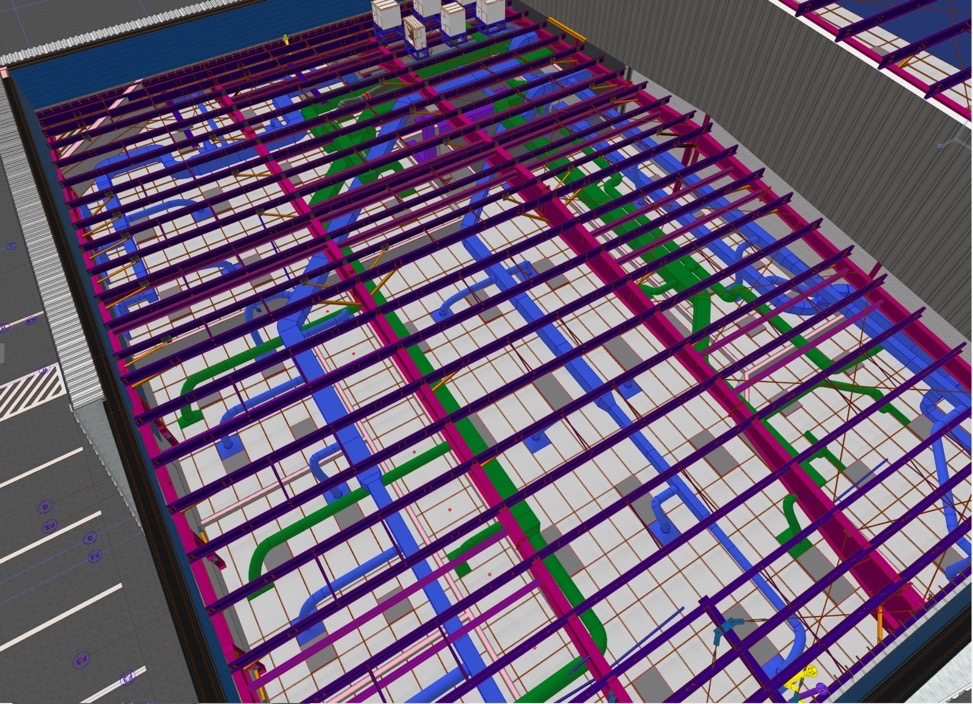

Resin works to keep everything in one model to the absolute highest level they can to avoid conflicts, even seeking further granulation so that a structural engineer could work in their model regardless of the software they’re using.

“Increasing that level within the software would make it possible for us to say if this component has absolute structure, what portions of that product do we as an architect actually want to, or should we have control over, and which things can we give full control to and a bounded playground for the structural engineer. As an architect, I am confident, seeing that there are no clashes and it’s going to work. And that just brings me a huge peace of mind for moving further and getting ready into actual construction because it’s all there in front of me as they do it.”

It boils down to assisting the party responsible for coordinating collisions and conflict. Establishing an integrated building team within the framework of Archicad. In terms of efficiency and profitability standpoints regarding bringing in a structural or mechanical engineer earlier into the design – the team can resolve issues before they become real issues on the job site.

Resin currently has a large mixed-use commercial project that is nearing completion of the schematic design phase. Thanks to the coordination in Archicad, the team has engaged their structural engineer thus being able to make informed decisions very early on about column grids, spacing, about structural lines, about where shear walls might need to be located.

“The beauty is they’re not just looking at lines on paper or evaluating it from PDFs. They can go in and spin around the model at their convenience, whether that’s sometime between 8:00 and 5:00 or whether that’s at 11:30 at night. They don’t need to then depend on a conference call from us to go and learn more about the project. And so there’s power number one. We can bring them in early and we desire to bring them in early.”

Permissions levels this early can be limited so that valuable input and reliable feedback can add to the collaboration. Whipple says this achieves the silo elimination – the so-called Holy Grail of integrated design.

“GRAPHISOFT has long championed eliminating the silo approach. We want that too.

Graham Whipple, Principle

“GRAPHISOFT has long championed eliminating the silo approach. We want that too. We want our teams coordinating to the highest level we can right now from the earliest stages on. And so our structural engineer is already in here. We’re ready to release a package (on the mixed-use project) and do a kickoff with our full engineering team. And the most critical portion, the structural engineering in this, the thing that is most likely to cause conflicts with our ducting, and plumbing routing, and complexities there, they already are familiar with our project. When they do come in – they are an informed voice during that kickoff collaboration.”

When the time comes for Elemental MEP to add their voice, they too will be informed, says Whipple. “That’s because we already put thought into the major raceways and chases, mechanical areas that are needed to allocate space for ducting, plumbing, and electrical. The structural engineer has been made aware that those are sacred areas in the building. This level of integrated design speeds the process, streamlining it because each team is in the model becoming familiar with the project.”

The real-time and live collaboration is supported by using Teamwork functionality including live chat, permission request or having all parties in the model simultaneously. Resin occasionally has an engineer working at odd hours – a coordination call at four o’clock in the afternoon allows for prep and resolving questions that may not be able to be addressed in the model, the latter being the least frequent occurrence.

“The mechanical, electrical, and plumbing engineers now have the same permission level that a structural engineer had a month ago or two months ago, depending on the speed of the project. But now they can get in and they can start discovering the routing opportunities and potential. And we have now a very informed dialogue rather than just working off a building section, and floor plan, and maybe select snapshots. So having them in our same model and having them unafraid to navigate through our model, as far as efficiencies in construction, in the overall budget, in avoidance of change orders, (which happens when team members do not understand the building). Integrated design kick starts problem solving.”

You might also like:

More Articles:

Archicad

Customer Stories

Education

Industry News

Tips, Resources + Downloads

Webinar Recordings